Industrial robots have become an essential component of modern manufacturing. They increase production and quality by repeating tasks with precise movements, few errors, and no need for breaks. They can also replace human workers on tasks with poor ergonomic conditions or exposure to hazardous materials or equipment. Many manufacturers are investing in collaborative robots, a.k.a. cobots, which can work safely in proximity to humans.

Because of these capabilities, industrial robots have become indispensable in many industrial processes. Here are five of the most common applications for these programmable machines:

1. Picking, Packing, and Palletizing

Because they run the same program over and over automatically, industrial robots can sustain levels of production and quality that most humans cannot. This is especially true of speed, consistency, and dexterity over the course of an 8-hour shift. Robots can select and organize materials and then deliver them to a warehouse shelf or a workstation on the shop floor. Palletizing robots are found in industries like manufacturing, food processing, warehousing, and shipping.

Industrial robots show their value particularly in settings where products are handled several times before shipping. They help reduce direct labor costs while sparing human workers from repetitive tasks.

2. Assembly Line Operations

Industrial robots are ideal on the assembly line. They eliminate production bottlenecks by working continuously and accurately. For example, in auto plants, they can attach door handles, windshield wipers, hoods, and wheels, freeing human workers for higher-value tasks.

Assembly robots are also excellent for consumer electronics, computers, and medical devices, in which components are too intricate for human hands, and accuracy is essential. They do their assembly work without breaks or injuries, increasing output and reducing costs.

3. Material Removal and Polishing

Manufacturers are turning to industrial robots to offset today’s skills shortage. Material removal includes machining, cutting, deburring, sanding, and polishing. Because of their speed, agility, and accuracy, industrial robots are a perfect fit for manufacturing tasks that require close attention to detail and cause worker fatigue, such as material removal. Examples include machining, cutting, deburring, sanding, and polishing. And by removing humans from the factory floor, manufacturers have improved their plants’ overall safety and eliminated costly human error.

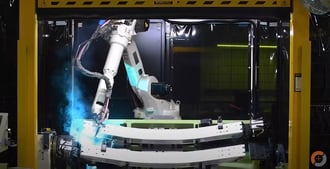

4. Welding Robots

Welding is a hazardous and time-consuming task that is often well suited for industrial robots. Whether in steel fabricating or automotive manufacturing plants, robots handle the parts and perform the welding. They can perform consistent MIG, TIG, plasma, or spot welding with shorter cycle times, efficiently use shielding gas and other consumables, and have consistent weld quality.

Another advantage is that human workers are not subjected to the toxic fumes and burns associated with welding. Companies that employ robots also see a marked improvement in production efficiency.

5. Painting Robots

Industrial robots surpass humans in painting efficiency and uniform application. While painting can be an inexact and time-consuming process for human workers, robots apply coatings with high precision and speed every time. The paint is delivered using a metering system and spread by combining a robotic arm and sprayer tooling to coat the part accurately, even on complex shapes.

Ideal for small and hard-to-reach components, industrial robots are easily reprogrammed to coat different parts or change patterns. They can even be equipped to accommodate rapid changeover from one part to another. While robotic painting is typically thought of as a mainstay of automotive production, other industries use this technology to improve product quality and consistency too, such as prefabricated construction and furniture manufacturing.

Could an Industrial Robot Improve Your Bottom Line?

We can help you find the answer. By partnering with the experts at Force Design, you have access to over 20 years of automation experience. We can find a solution that meets your needs. We specialize in robotic applications and industrial automation, and we’re ready to assist you. Connect with us today!