What do you imagine when the subject of manufacturing robots comes up? Like many people, you probably picture a row of ten-foot-tall robotic arms doing welding and assembly operations to vehicles moving along a production line. Or perhaps you imagine a single robot, isolated or fenced in, doing a process deemed too dangerous or difficult for human workers.

The original manufacturing robots were engineered to do a single task, such as making one component, welding the same couple of seams, or spraying coatings on identical parts. Once a part was phased out, the company brought in another robot to replace the outdated machine or repurpose it for the next product. The investment required for this early technology was beyond the reach of most small to mid-size manufacturers, so it remained available to only the largest industrial operations.

Fast Forward to 2021

While large businesses still employ those industrial behemoths, technological advances, such as sensors, programmable controls, safety features, software and AI, and innovative end-of-arm-tooling, have resulted in a new style of a smaller robot that fits in comfortably and safely with its human coworkers.

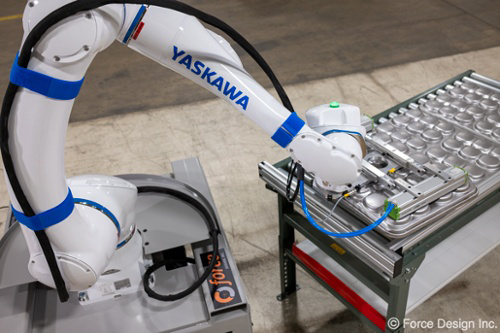

Called collaborative robots (or cobots) these versatile models have made robotics accessible to almost any sized manufacturer in numerous settings. Intuitive software and graphical user interfaces (GUIs) have removed many programming challenges, while integrated safety features permit cobots to “collaborate” with their human counterparts in performing complicated operations. Adding to their flexibility and cost-effectiveness, cobots can be reprogrammed and retooled to swap between tasks in the same facility.

Several types of collaborative robots are available, many of which can be incorporated into existing manufacturing production systems. Accessories and tools like vision cameras, welding tips, and vacuum grippers to pick and place flat trays, can also be added.

What Types of Tasks are Within a Cobot’s Capabilities?

Despite reports to the contrary, cobots are not designed to replace human workers entirely. Instead, they work with humans, taking on the parts of a process that are repetitive or dangerous enough to risk injuries. Their small footprint and dexterity make them excellent assistants for the following tasks:

- Pick and place (see the Force Design Collaborative Robot System video)

- CNC machine tending

- Packaging and palletizing

- Finishing processes including deburring, trimming, and polishing

- Quality inspections

- Assembly

- Painting, coating, and dipping

Keep in mind that this is far from being an exhaustive list. Accessories and technologies are continuously evolving, and applications are expanding into more industries. And each new method using cobot technology will transform human involvement. However, for the foreseeable future, certain aspects of the workplace will remain in the hands of humans.

Are you Looking to Add Automation to Your Manufacturing Operation?

Partner with the experts at Force Design. With more than 20 years of automation experience, we can find solutions for your unique business requirements. We are the specialists and are here to help. Contact us today!