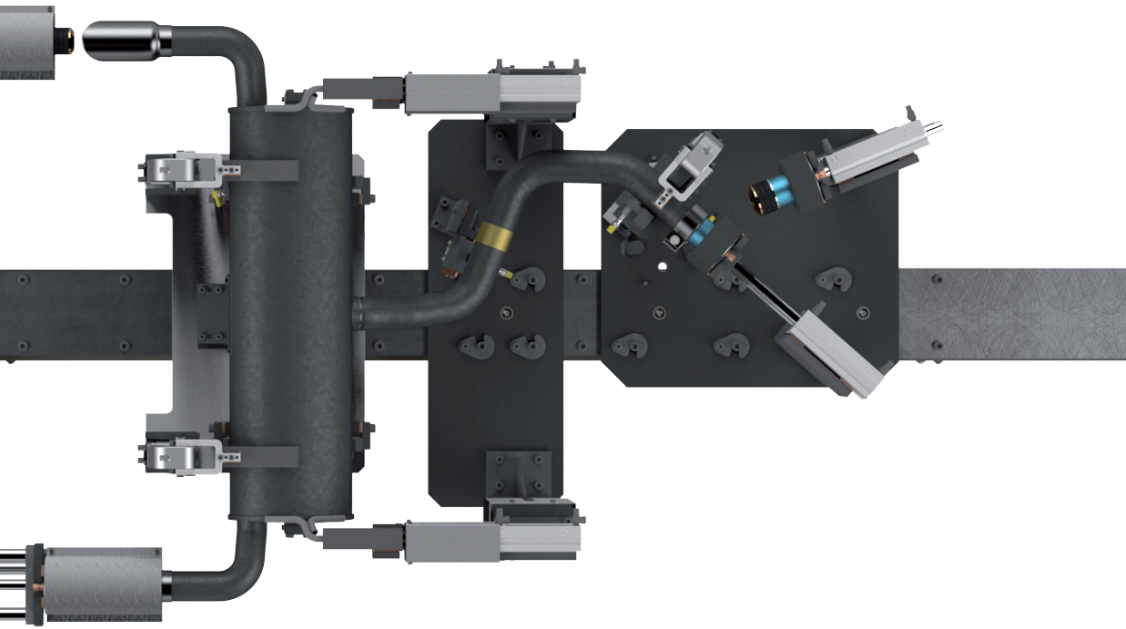

Custom Robotic Automation Equipment

Improve your manufacturing processes with equipment designed specifically for your business.

Boost employee happiness.

Increase production efficiency.

Produce higher quality products.

Take the Frustration Out of Your Manufacturing Process

You understand better than anyone the details of your day-to-day operations and how they fit together. You also know the most frustrating, stressful parts of your process and what it’ll take to fix them. We’ll help you do it.

As automation experts, we’ll design, build, and implement custom robotic automation equipment, so you can improve your process, reach your manufacturing goals, and do great work with confidence.

25 Years of Automation Excellence

At Force Design, we know you want to be proud of the work you do. In order to get there, you need to have reliable equipment. The problem is that frustration can build when your setup isn’t quite what you need.

We believe you should have exactly what you need to succeed. We understand the frustration that comes from not having the tools and resources you need to do your best work. That’s why, for over 25 years, we’ve provided custom robotic automation equipment that improves operations for businesses like yours.

If you’re interested in a better setup, connect with our team today. We’ll work with you to create an automation strategy that’s right for you, so you can have the equipment you need to reach your manufacturing goals and do great work with confidence.

In the meantime, check out our case studies to see real-life examples of how our equipment has made a difference for others who have been in the same position as you. Don’t wait. Connect with our team today, so you can stop feeling frustrated and stressed at work and instead, finally get the equipment you need to improve your processes and be proud of the work you do.

Let’s Get to Work!

1

Connect With Us

Work with our team to create an automation strategy that’s right for you.

2

Get Customized Automation

Have the equipment you need to meet your goals.

3

Do Great Work

Reach your manufacturing goals with the right equipment and ongoing support.

How Much Does This Cost? Find Out!

Check out a recent case study with all the details to find out what custom robotic automation equipment really means for businesses like yours. Enter your name and email below, and we’ll send it straight to your inbox.

How Much Does This Cost? Find Out!

Check out a recent case study with all the details to find out what custom robotic automation equipment really means for businesses like yours. Enter your name and email below, and we’ll send it straight to your inbox.

How Much Does This Cost? Find Out!

Check out a recent case study with all the details to find out what custom robotic automation equipment really means for businesses like yours. Enter your name and email below, and we’ll send it straight to your inbox.